Test ring for heat exchanger. 04012009 1209 AM.

Bn Ds T13 Typical Construction Details For Test Rings Of Floating Head Type Exchangers

HYDRO 39 26 CORROSION ALLOWANCE 3 3.

. ANSON can manufacturer various kinds of floating head heat exchangers accordance with the TEMA API660. 13 This Standard is applied to heat exchangers designed beginning with. Design pressures range from full vacuum to 6000 psi.

Figure 2 is a fragmentary central vertical section through a heat exchanger of the typev4 described and having a test ring secured to the tube sheet and the shell enclosing the same. They can be used for wide temperature and pressure range. Mechanical components of a heat exchanger is important to understanding how they function and operate.

Both are water source heat-pump loops both heat exchangers are approx 6 years old. Shell and tube heat exchanger. Out of all different types shell and tube heat exchangers are quite popular and widely used for a variety of applications.

This is ordinarily accomplished by placing a split ring flange behind the tubesheet and bolting a head or a flat cover up to it with some sort of gasket usually an o-ring placed in between-Christine. CCB 1052 ENGINEERING DRAWING PROJECT 1 INDIVIDUAL HEAT EXCHANGER NAME. EO 12 Provided with a drawing of a heat exchanger IDENTIFY the following internal parts.

1 heat exchanger is piped with the boiler water flowing thru the shell and it has more than enough capacity. Shell and Tube Exchangers. You may want to review shell and tube heat exchanger inspection procedure and related inspection and test plan.

Heat Exchangers are pieces of process equipment built and designed for maximum efficiency of heat transfer between two different machines or mediums. Its channel head flange is integral type. A shell and tube exchanger consists of a number of tubes mounted inside a cylindrical shell.

Shell tube heat exchangers. Great info One thing I was looking for but did not find is the preferred way to pipe a tube shell heat exchanger I have a problem with 2 buildings connected with a central boiler plant. Vertical installation is usually recommended.

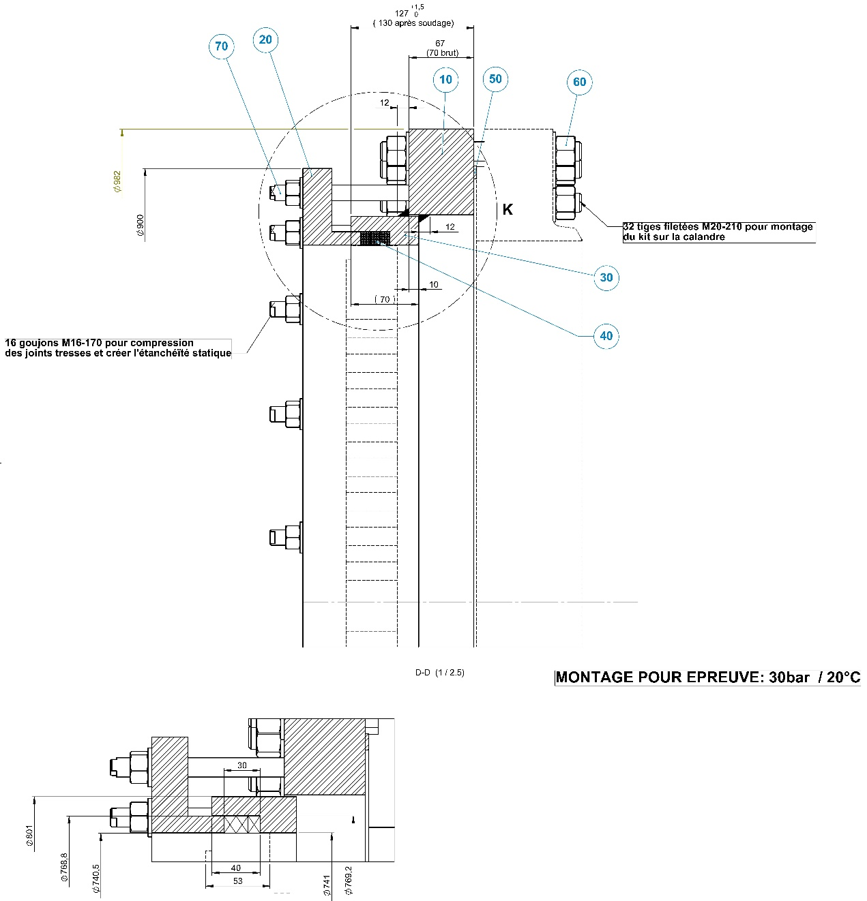

Plate Fin Type Exchangers. Different types of heat transfer equipment is widely used in the process industry to heat up or cool down process fluids. This hydraulic test ring was manufactured by Quiri for a tubular heat exchanger with floating head type TEMA AES.

EO 11 STATE the two types of heat exchanger construction. Well the exchanger is TEMA type - BHU. Unit kgfcm2 g c kgfcm2 g mm nos.

Much of the equipment used in the refining and processing industries is known as Process Equipment. Generally there are four basic types of floating head heat exchanger outside packed stuffing box TEMA P outside packed lantern ring TEMA W the floating head with backing device TEMA S and pull through TEMA T designs. The shell-and-tube heat exchanger is by far the most common type of heat exchanger used in industry.

Floating Head Heat Exchanger Estimation Drawing Spreadsheet. Sheets Screenshots 36. C radiography full spot joint efficiency 1 085 corrosion allowance 0 3 no.

The Heat Exchanger Inspection article provides you with information about the inspection of the heat exchanger and heat exchanger testing during the manufacturing phase as well as in-service inspection in operating units. In most industrial processes the loss of heat is very. The weight of your heat exchanger either empty or full of water is indicated at the beginning of this manual and on the assembly drawing.

The fluid temperature inside the shell and tube are different and this temperature difference is the driving force for temperature exchange. Test rings allow the owneruser of a shell and tube heat exchanger to hydrotest the tube bundle while its outside of the exchanger. Qty company name client date title enquiry no.

Items test flange and test ring customised as per drawing application heat exchanger material grade - sa-266 gr4 of asme sec-ii part-a ed-2019 1. General requirements as per sa-788 of asme sec-ii part-a ed-2019-. Any concrete foundation or floor must be adequately designed to support the Polybloc heat exchanger and its contents.

This test is carried out once the heat exchanger manufacturing process is completed. Prepared by MPANNIRCHE 1 TABLE OF CONTENT TITLE PAGE 1Fundamental of heat exchanger 2Principles of heat exchanger 3Types of heat exchanger 4. The general principles of the mechanical design of the following types of exchangers are given in the Heat Exchanger Design Handbook 1994 and full descriptions of each are given under the corresponding entries in this encyclopedia.

A test head assembly for heat exchanger tube bundles consists of a structural frame to support the bundle test heads sealing devices between the test heads and the tube sheets clamps securing the test heads to the bundle with the sealing devices therebetween a supply reservoir for the test fluid a collection reservoir to receive the test fluids after testing to permit proper. Stabilize heat exchanger flow to within - 0006 ls 01 GPM and. 1 tema class r eff.

Picture 1 in fig 24 is for loose type flanges. This test consists in filling the equipment with water while it is subjected to pressure as indicated by the ASME code to be discussed later. Hta m² 7649 200 100 test press.

Shell and tube heat exchanger is a device where two working fluids exchange heats by thermal contact using tubes housed within a cylindrical shell. Flange rating 300 300 Backing Ring 140 1258 1414 1338 BODY FLANGE SS Nozzle schedule 80 80 TIEROD. Exchanger inlet C Flow through heat exchanger litersmin 20 1 4 8 and 16 40 1 4 8 and 16 60 1 4 8 and 16.

Of passes 1 2 heat treatment na na design code asme sec. 124 Test pressure Pt The test pressure is commonly known as hydrostatic test pressure. Charge the tank to the selected temperature and set the heat exchanger inlet temperature at the selected differential above the tank.

Lets look at a typical shell tube heat exchanger diagram to understand its structure. Two fluids can exchange heat one fluid flows over the outside of the. 12 For purposes of this Standard the designation shell-and-tube heat exchanger covers heat exchangers in general and heaters coolers reboilers and other shell-and-tube heat exchanging equipment.

It can be fabricated from a wide range of materials both metallic and non-metallic. FLOATING HEAD Heat Exchanger General Assembly view Shell side Inlet Shell side Outlet Tube side Inlet Tube side Outlet Shell Back Cover Distributor Tube Sheet Gaskets Gasket Saddle Floating Head Bundle Floating Head Heat Exchanger Cross Sectional View Baffle Shell Distributor Back cover Tube Bundle Floating Head Split ring FLOATING HEAD Heat Exchanger. Figure 1 illustrates a typical unit that may be found in a petrochemical plant.

This device is an indispensable tool for checking the tightness of the tube connection on the floating tube plate. I I Figure 3 is a fragmentary section to an enlarged scale of part of the floating head. The test ring is necessary to carry out the ten-year hydraulic test in the presence of the authorized inspector.

You mean Test Ring would act as a loose type flange during hydrotesting and it should be designed accordingly no matter if the channel head flange is integral type.

Floating Head Heat Exchanger Ppt Video Online Download

Heat Exchanger Test Ring Spare Parts Quiri

Bn Ds T13 Typical Construction Details For Test Rings Of Floating Head Type Exchangers

Floating Head Heat Exchanger Maintainance

Heat Exchanger Test Ring Spare Parts Quiri

Check List For Reviewing Of Shell Tube Heat Exchanger Drawings Pdf What Is Piping

0 comments

Post a Comment